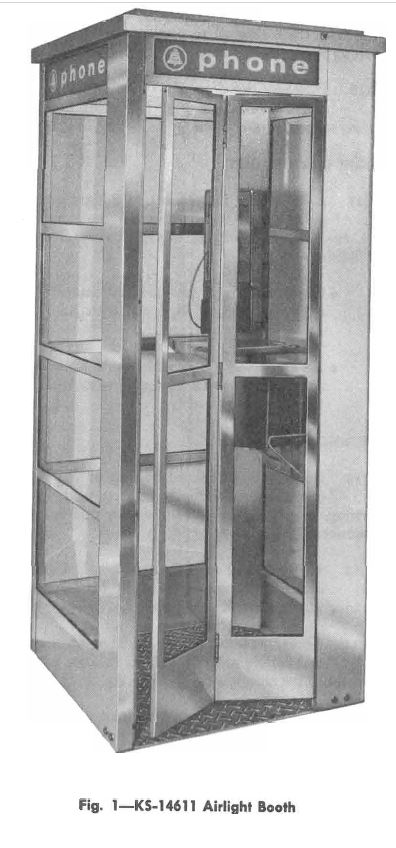

| Name | AIRLIGHT BOOTH |

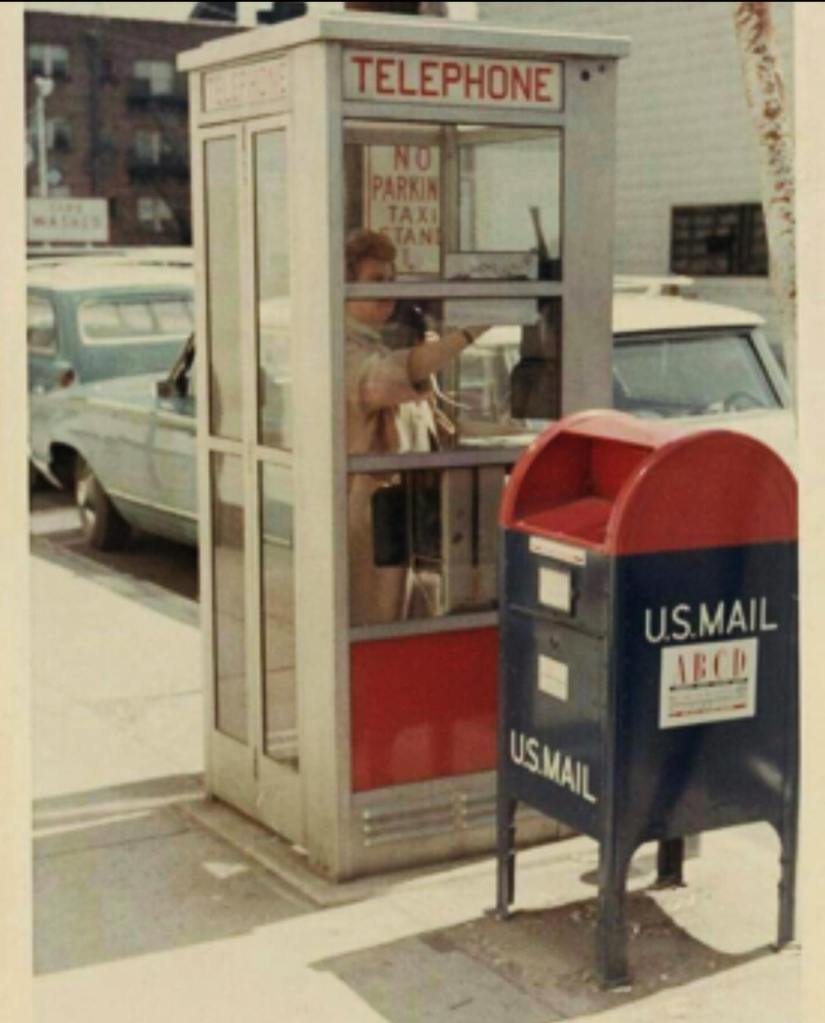

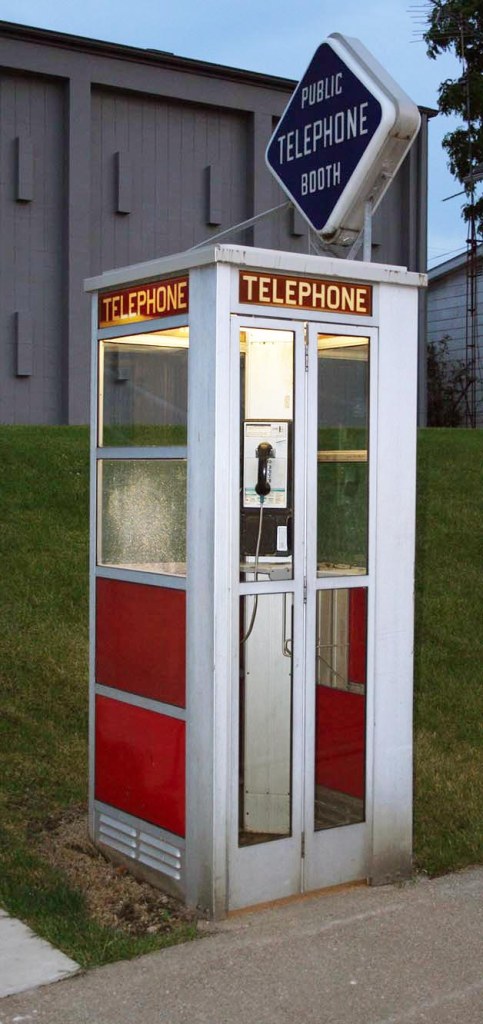

| Date | 1954 – First introduced by Bell System December 18 1953 Bell System announces New All-Metal Outdoor Telephone Booths. |

| Manufacturer | Various (design by AT&T’s Bell Laboratories). The Airlight was a Bell System booth, designed by Bell Labs, manufactured for Western Electric, and installed by local Bell operating companies. |

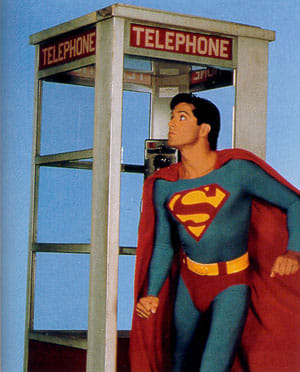

| Usage | US Phone Booth |

| Further notes |

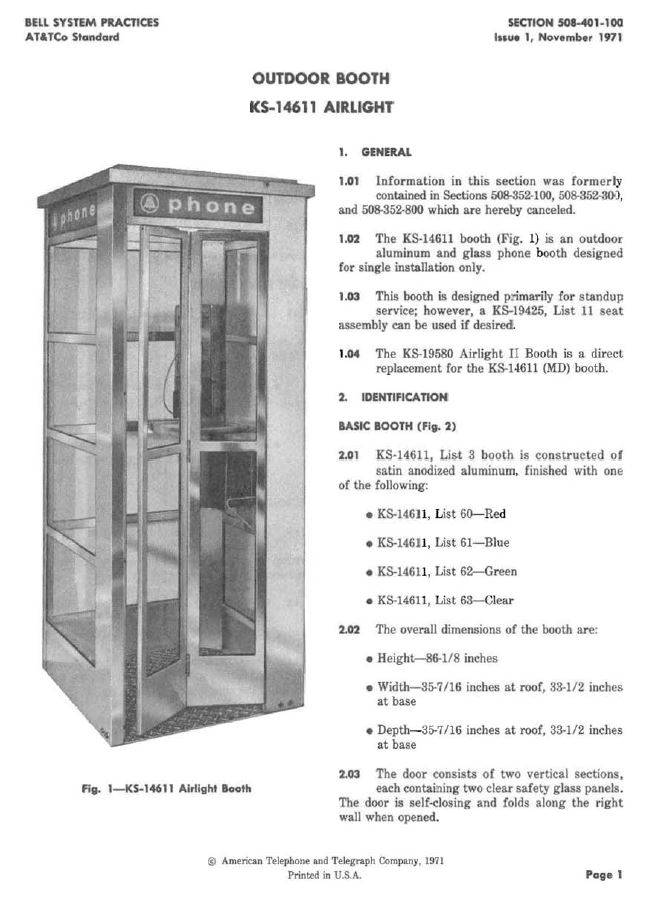

| The Airlight Outdoor Telephone Booth (the famous aluminum-and-glass design with a peaked roof) was indeed a Bell System booth, but it was not actually made by AT&T/Bell Laboratories themselves. Here’s how it worked: Design & Standardization: AT&T’s Bell Laboratories created the design standards for the Airlight booth in the early 1950s, and Western Electric (AT&T’s manufacturing arm) coordinated production. Manufacture: The booths themselves were built under contract by outside companies such as C&E (Coffman & Ewing) and others, to Bell System specifications. Western Electric didn’t fabricate the booths directly but controlled design, testing, and quality. Deployment: From about 1954 onwards, the Airlight became the standard outdoor payphone booth across the United States for the Bell System companies. It replaced earlier wood or steel kiosks with a modern, weatherproof aluminum-and-glass enclosure. So: 👉 The Airlight was a Bell System booth, designed by Bell Labs, manufactured for Western Electric, and installed by local Bell operating companies. breakdown of who actually built the Airlight outdoor telephone booth for the Bell System: Western Electric (AT&T’s manufacturing arm) Didn’t physically fabricate the booths in-house, but acted as the prime contractor. Set the specifications, did testing (including wind, heat, and vandalism resistance), and controlled distribution. Subcontracted actual production to specialized fabricators. Major Known Manufacturers Coffman & Ewing (C&E) – one of the earliest and most prolific builders of Airlight booths in the 1950s–1960s. Pittsburgh Steel Company – supplied aluminum and steel components. General Bronze Corporation – built aluminum and glass versions, often for areas needing weather-resistant structures. Associated Plastics / Kingsley (later for glazing and door assemblies). Design Features That Were Standardized Extruded aluminum frame, clear anodized finish. Tempered glass panels on sides and door. Aluminum peaked roof with illuminated “TELEPHONE” signs on all four sides. Ventilation slots in the roof. Floor panel (often ribbed aluminum). Timeline 1954 – First introduced by Bell System as the “Airlight Outdoor Telephone Booth.” Late 1950s–1970s – Became the standard outdoor booth across the U.S., replacing older wood and steel kiosk types. 1980s–1990s – Production tapered off; booths were refurbished or phased out as payphones declined. Immediate Predecessor to the Airlight (Late 1940s–early 1950s) Western Electric Outdoor Booth, Model 1A & 1C (ca. 1949–1952) Boxy, aluminum-and-glass construction, but heavier and less refined than the later Airlight. Had illuminated “TELEPHONE” panels on top, but the roof design was flat or minimally pitched. Ventilation was a problem — they got very hot inside. Maintenance-heavy: glass and steel fittings often corroded or warped. |

Leave a comment